Estimated reading time: 7 minutes

Introduction to Tailfin Axles

What are Thru Axles and Quick Release (QR) Skewers?

One of the distinctive features of a Tailfin Rack or AeroPack is how we use the wheel axle to secure the system to the bike. Whilst it’s true that you can also mount a Tailfin system using frame mounts, it’s when using the axle that the full strength and security of our design reaches its peak.

QR Skewers

Barring the last four or five years the most common type of wheel fixing was the quick-release (QR) skewer. This simple system relies on a cam-activated mechanism operated by hand and provides a quick and effective solution for holding wheels in place.

A very simple and reliable design, it helpfully comes in one size and standard. So if your bike runs with a QR Skewer, you needn’t read on any further, just select the option ‘QR Axle’ when asked for your ‘Axle Type’.

Thru Axles

The widespread adoption of disc brakes, firstly by mountain bikes and more recently by road and gravel bikes highlighted some specific failings of the quick release (that of inconsistent clamping forces and poor alignment between hub and frame dropouts resulting in brake alignment issues) when used with this more modern style of braking.

To mitigate this issue the bike industry developed what we call the thru axle (or bolt thru axle). This larger diameter wheel fastener threads securely into the frame itself through well-toleranced circular dropouts and provides much more consistent alignment and clamping force that minimises frame/fork compression and the resultant annoying brake rub.

The Tailfin Thru Axle

Why use a Thru Axle to Mount a Rack?

Using the rear wheel’s ‘axle’ as a key attachment point for the Tailfin system was the result of identifying the strongest part of the bicycle in terms of load bearing. Spreading the forces of any additional load to the axle isolates them from potentially causing stress on the relatively delicate rear triangle of the frame. Additionally, in case of a catastrophic failure either through overloading or an accident, the axle is a relatively inexpensive item to replace and should not result in writing off your precious frame.

Thru Axle Pitch Threads

Being fueled by competition the cycle industry is notoriously reluctant to settle on universally accepted standards and brands are keen to adopt unique and specific designs in order to stand out from the crowd.

The thru axle is a victim of this process and one of the roadblocks we encountered when designing the Tailfin axle was the multiple standards that have been adopted by various manufacturers.

Not only does the thread pitch (the angle and spacing of the raised thread) change between designs, but also how the axle fits within the frame itself. This is why the Tailfin axle is available in four different thread pitches and why each axle comes with four differently-shaped end caps.

How to attach a Tailfin system to the axle

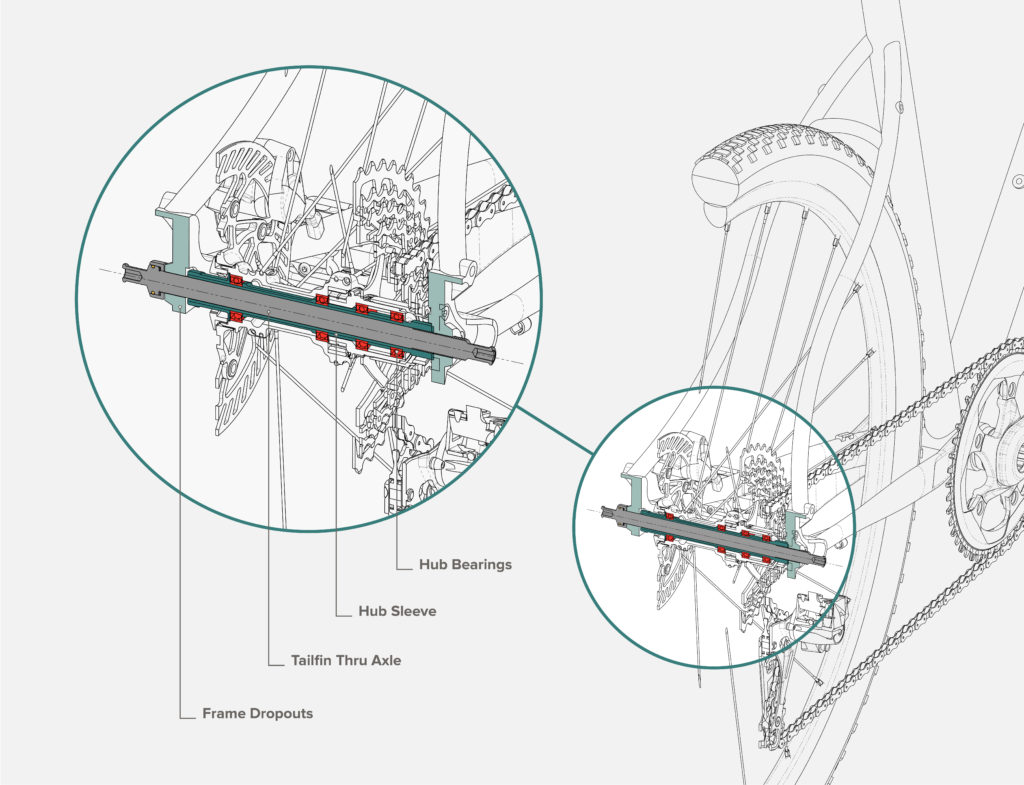

Look at the diagram below, and you will by now notice that the replacement Tailfin Axle has a smaller diameter extension at each end of the main axle.

These extensions are designed to stick out further than the existing axle and provide a solid mounting point for each side of the Tailfin Arch, via our Fast Release Dropouts. The length of these extensions has been carefully chosen to ensure there is zero risk of fouling when riding your bike without a Tailfin fitted, meaning the tailfin axle can be seen as a permanent replacement for your old axle.

You will also notice that the extensions feature machined ribs on the mounting surface. These are designed to prevent the Fast Release Dropout from sliding about. It’s also why the dropouts feature nitrile bushings that conform to these ribs and create an incredibly secure connection without rattle or movement.

Axle materials

Tailfin thru axles are individually CNC machined from solid stock 7075-T6 aluminium alloy and further processed with an anodised finish in classic Tailfin Black. 7075-T6 alloy was chosen as it has the ideal attributes for this application: high strength-to-weight ratio, resistance to fatigue and corrosion plus excellent overall toughness. The fact it was originally developed for aircraft space frame construction should tell you all you need to know.

On average a Tailfin Axle with additional hardware weighs 69 grams – standard bolt-thru axles weigh between 45-75 grams – so the trade-off is very minimal.

Fitting and compatibility advice

How to fasten the axle in the frame

Due to the unique shaping of the Tailfin thru axle, it is very difficult to incorporate any form of lever or handle into the design and still retain simplicity and low weight. Instead, the ends of the Tailfin axle are machined to accept a standard 5mm Hex or Allen-style tool, something every rider will have on their multitool. The 5mm recesses are machined deep enough to provide a very positive fit with all tools to reduce the chances of slippage and potential rounding off of the axle end, which can happen with some axles.

Whilst we will always recommend you to tighten the Tailfin axle ‘hand tight’ in your frame (using a 5mm hex key of course) individual frame manufacturers will recommend differing specific torque settings. If in doubt refer to your friendly local bike shop for guidance on how tight an axle should feel in your frame – you shouldn’t need two people and a huge metal bar to undo the axle but equally, the Tailfin Axle shouldn’t be able to be loosened just by hand.

For further instructions on the thru-axle, see the assembly guide here.

Boost, Super Boost, and Regular fit

Key considerations were covering different thread pitches, axle seat shapes, and frame spacing/widths. As it stands, we produce four different axles based on the four most common thread pitch standards: 1.0mm, 1.5mm, 1.75mm, and 1.0mm Speed Release.

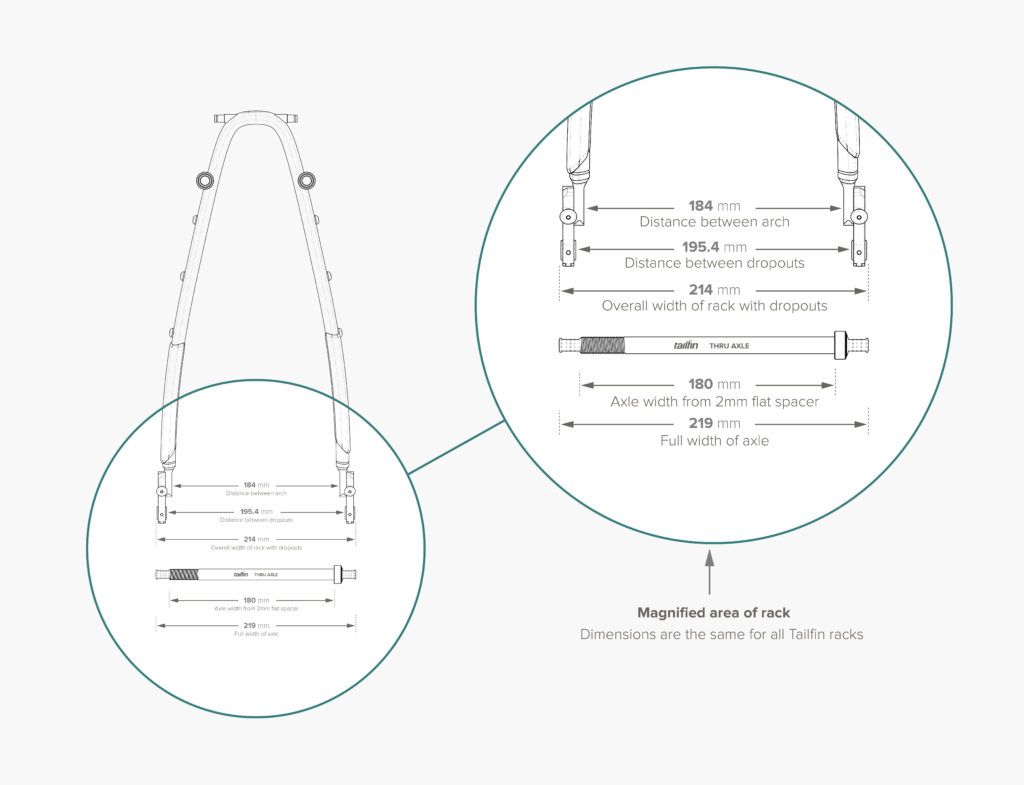

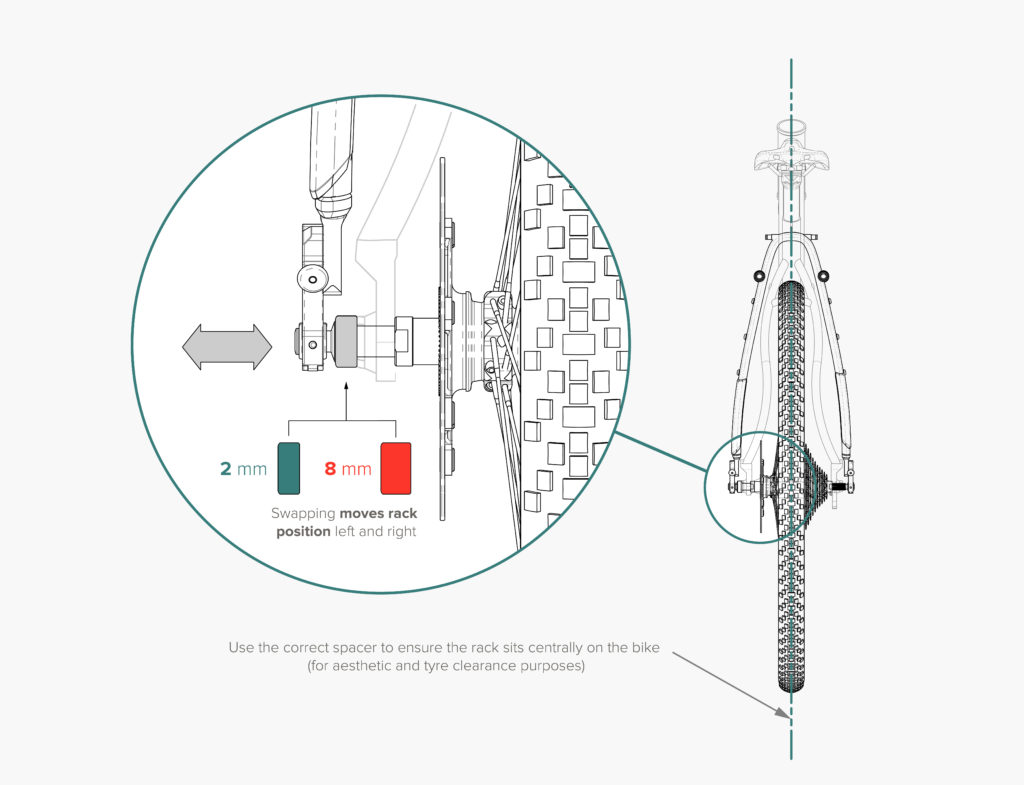

Each version of the Tailfin Axle ships with four different axle seat spacers: 2mm flat, 2mm cone, 8mm flat, and 8mm cone. These primarily are to make sure the axle sits flush with the frame and creates a solid interface for a strong and reliable connection. The secondary reason for providing the different heights of the spacer is so you can maintain an equal amount of axle showing at each side of the bike. This helps centre the Tailfin system on the bike and prevents uneven loading.

Offering spacers of different widths also allows us to produce a single length of the axle that will easily fit the majority of common rear hub/frame spacing. The axle will fit most 135, 142, and 148mm spaced rear ends. At the moment, we cannot accommodate the rarer 157, 177 or 197mm rear hub spacings. If this is your bike we recommend frame mounting if you want to run a Tailfin.

Additional considerations

In some instances, specific bike brands also adopt additional proprietary features within the rear thru axle design that has led us to provide a variety of additional adapters to ensure further compatibility. Focus and Cervelo have adopted a keyed R.A.T. axle system requiring additional parts. Salsa and OPEN also have further requirements in the form of replacement nuts or additional locking nuts. We now also produce an adapter for brands that have recently adopted SRAM’s new UDH (Universal Derailleur Hanger) system.

How to Select Your Axle (Video)

Watch the Video Guide:

Use the Tailfin Axle Finder Tool here.

We have gathered an extensive database of bike brands, specific models, and model years and placed it into an easy-to-use axle finder to enable riders to take the uncertainty out of getting the right thru-axle.